Bright Annealing

Bright Annealing

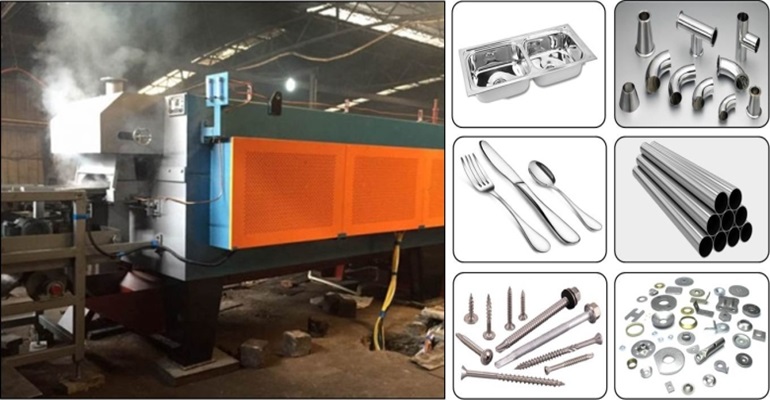

Our advanced Bright Annealing process is designed with meticulous temperature control, heating stainless steel tubes to a precise range of 1040°C to 1080°C, followed by rapid cooling through quenching water. To further enhance surface quality, we use 99.999% pure hydrogen, ensuring a flawless finish that meets the most stringent quality standards.

At JCM Stainless, we are dedicated to providing stainless steel solutions that excel in hygiene, durability, and performance. This commitment makes us the trusted choice for customers who demand superior stainless steel products.

| Sr.No. | BRIGHT ANNEALING | SOLUTION ANNEALING (Annealing & Pickling) |

|---|---|---|

| 1. | Under Reducing Atmosphere [ N₂ & H₂ blanketing] | Under Oxidation Atmosphere [ presence of O₂ ] |

| 2. | No oxidation possibility | Oxidation in part of process |

| 3. | No chemical effluents, Green Process | Highly polluting process with highly Polluting effluents. Not a green process. |

| 4. | No Oxidation, No pickling necessary. | Pickling necessary to remove oxidation formed during Annealing. |

| 5. | Smooth surface finish can reduce Contamination | Pitting and rough surface finish can create contamination. |

LOOKING FOR BEST STAINLESS STEELS PRODUCTS?

Best Stainless Steels Products Manufacturer

Make An Appointment With Us Today!