Quality

At JCM, we are committed to continually enhancing and altering our manufacturing and testing equipment to keep up with the current advancements. Being stainless steel pipe suppliers, we meet and satisfy our customers' specifications and expectations by delivering the best quality stainless steel tubes and pipes.

To ensure and maintain the quality of the products, a team of highly skilled and experienced engineers carries out quality tests with top-notch testing equipment on our site.

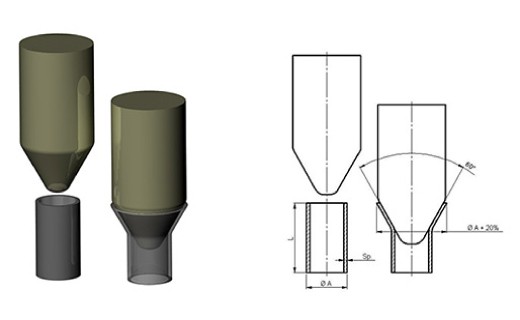

Flaring Test:

The flaring test is to assess the forming nature of pipes or tubes after expanding it in a press to a certain degree. This flaring test is executed by following the standard code requirements. All products which do not pass this test are rejected.

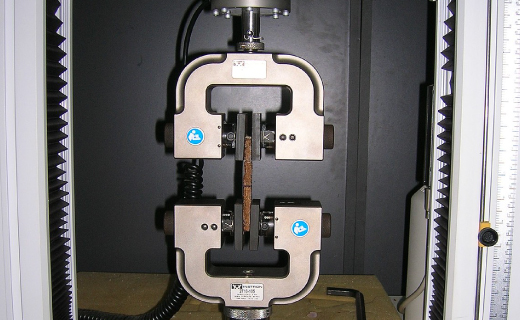

Tensile Test:

To determine the resistance and ductility properties of the products, the tensile test is performed. This test typically takes place under ASTM, DIN and BS standards, at room temperature.

Hardness Test:

Samples from each batch are verified to guarantee that the stiffness of the tube is within permitted limits by conducting a hardness test.

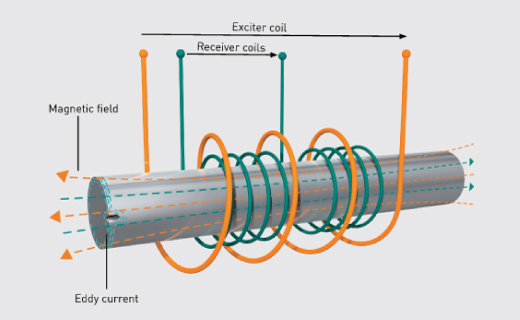

Eddy Current Test:

The eddy current test is conducted by following the test protocol outlined in the ASTM E-426. This test is for detecting hidden defects, cracks, and inhomogeneities of the product.

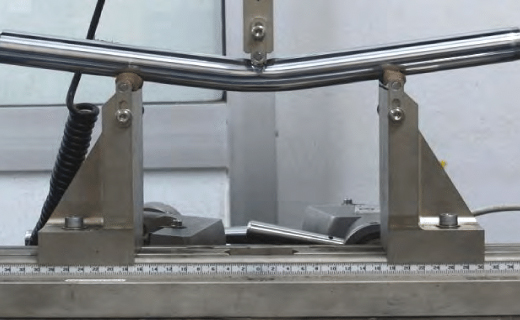

Bending Test:

A bending test determines a pipe's ability to withstand the pressure with no leakage.

Hydrostatic Test:

All pipes and tubes undergo a hydrostatic test that is performed at a pressure up to 450 kg/cm sq. This test is made possible by making use of extreme pressure plunger pumps.

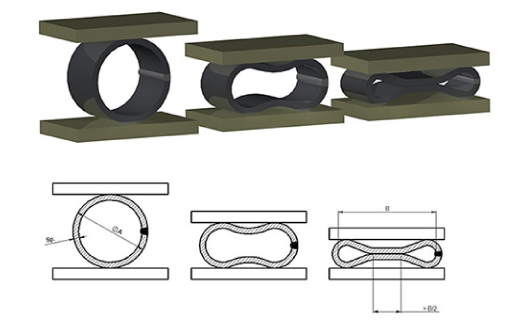

Reverse Flattening Test:

The reverse flattening test is executed to make sure that the welded part of the pipes has no breaks or blowholes.

RA Test:

To ensure that the surface of the product is desirable for a particular purpose, the roughness average test is conducted to examine the frequency and amplitude of the surface.