Stainless Steel Manufacturing Process

1

1. Infrastructure

Raw materials used are

stainless steel scrap, iron, nickel and chromium.

2

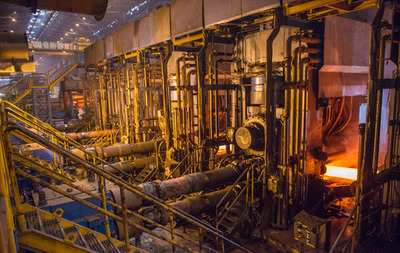

2. EAF

These substances are added into an

Electric Arc Furnace (EAF) where electrodes heat the mix to its melting point.

3

3. AOD Converter

The mix is then treated in Argon Oxygen Decarburization (AOD) Convertor where pipes blast Argon and Oxygen gases into it.

The AOD minimises undesired oxidation and removes excess carbon from the mix.

4

4. Vacuum Oxygen Decarburization

The mix is then treated in a tank degassing unit which is additionally equipped with an oxygen blowing lance. Due to reduced carbon monoxide partial pressure under vacuum condition, this process helps in

reducing the carbon content of high alloyed stainless steel grades.

5

5. Continuous Casting

The stainless steel mix is

cast into stainless steel slabs and blooms through a process called continuous casting.

6

6. Grinding

The stainless steel slabs/blooms go through a

grinding process to remove any surface defect that has occurred during casting.

7

7. Reheating

The stainless steel slabs are then reheated due to which a rusty scale (oxide) is accumulated on the surface. This scale is removed from the surface by

high pressure water jets in a process called as Descaling

8

8. Roughing Mill

The stainless steel slab is then sent back and forth through the Roughing Mill to

reduce its thickness and increase its length, without changing its width.

9

9. Finishing Mill

Having acquired the shape of a sheet, it is now sent to

further thinning in the Finishing Mill, depending on customer' requirement.

10

10. Coiling

These stainless steel slabs are now turned into plates (~20 mm thickness) or coils (~6 mm thickness) as per order after

several intermediate processes.

11

11. Annealing

The hot rolled (HR) coil undergoes a thermal process called annealing, in which the metal is given a consistent, uniform internal structure and homogeneous properties. This helps to

improve the mechanical stability and corrosion-resistance of the coil.

12

12. Pickling

The stainless steel coil then goes through a chemical process, Pickling, in which mill scales,

surface oxides, and annealing oxides are removed.

13

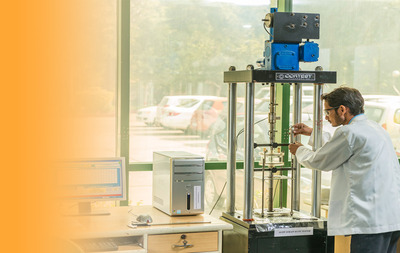

13. Quality Testing

There is quality testing at each stage of production, where a sample is taken from the product, and sent to labs for physical and chemical examination.

Each gram of our stainless steel is planned to perfection.

14

14. HRAP/CRAP Coils

The resultant product is called Hot Rolled Annealed Pickled (HRAP) stainless steel coil which goes either directly to the customer, or to be made into

15

15. Customization

CRAP coil goes through several production processes aimed at customising surface finish, thickness, product chemistry and mechanical properties.

Different kinds of stainless steel finishes such as CR, BA, and 2D/2B are produced during these processes.

16

16. Slitting

The stainless steel coils in Cold Rolling Division are reduced to

different widths as per the customer requirement.

17

17. SPD

For specialized applications and products such as coin blanks, strips for razor blades, and precision strips up to 0.05 mm thickness, our Special Product Division produces

highly sophisticated stainless steel products.